Technology

TECHNOLOGY NNPB (NARROW NECK PRESS AND BLOW)

Previously, a thick-walled and high-weight bottle production technique was used to ensure the durability of glass bottles. Due to the request of the beverage manufacturers and the negative effect of the weight of the glass bottles on the user, a glass production technique has been adopted. Hence, the thin-walled but internal pressure resistance is at the same level as the thick-walled glass bottles.

Thanks to this glass production technique, which stands for "Narrow Neck Press and Blow", in addition to manufacturing cost, the glass bottle's logistics and raw material costs were also reduced.

REGENERATIVE FURNACE

The waste heat coming out of the melting furnace passes through the bricks with honeycomb structure, and thanks to the bricks, which are heated up to 1100-1200 °C due to the waste air, the air coming from the outside is heated, thus saving in fuel consumption. At the GCA production facility, the regenerative furnace is operated with natural gas, an environmentally friendly and economical fuel.

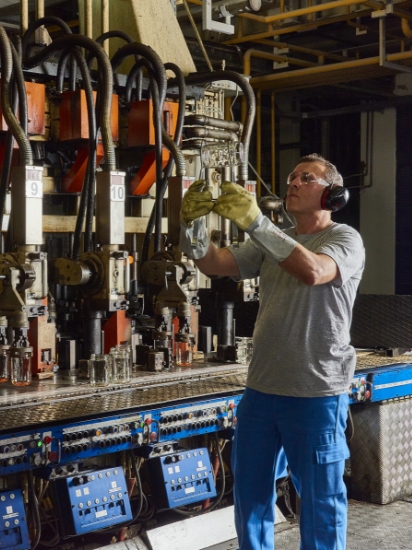

COLOR VISUAL CONTROL

All products are checked online by quality machines. In GCA, the product's side surface, finish, and base controls are controlled with the latest technology coloured light. Colour light technology makes it easier to detect and distinguish different defects beyond the black and white image.